最新消息

新闻

公告

_20251125_6961.png)

_20251125_6961.png)

鸿海研究院参展 HHTD25 展示布局下世代的科研成果

2025/11/25

鸿海研究院参展 HHTD25 展示布局下世代的科研成果

2025/11/25

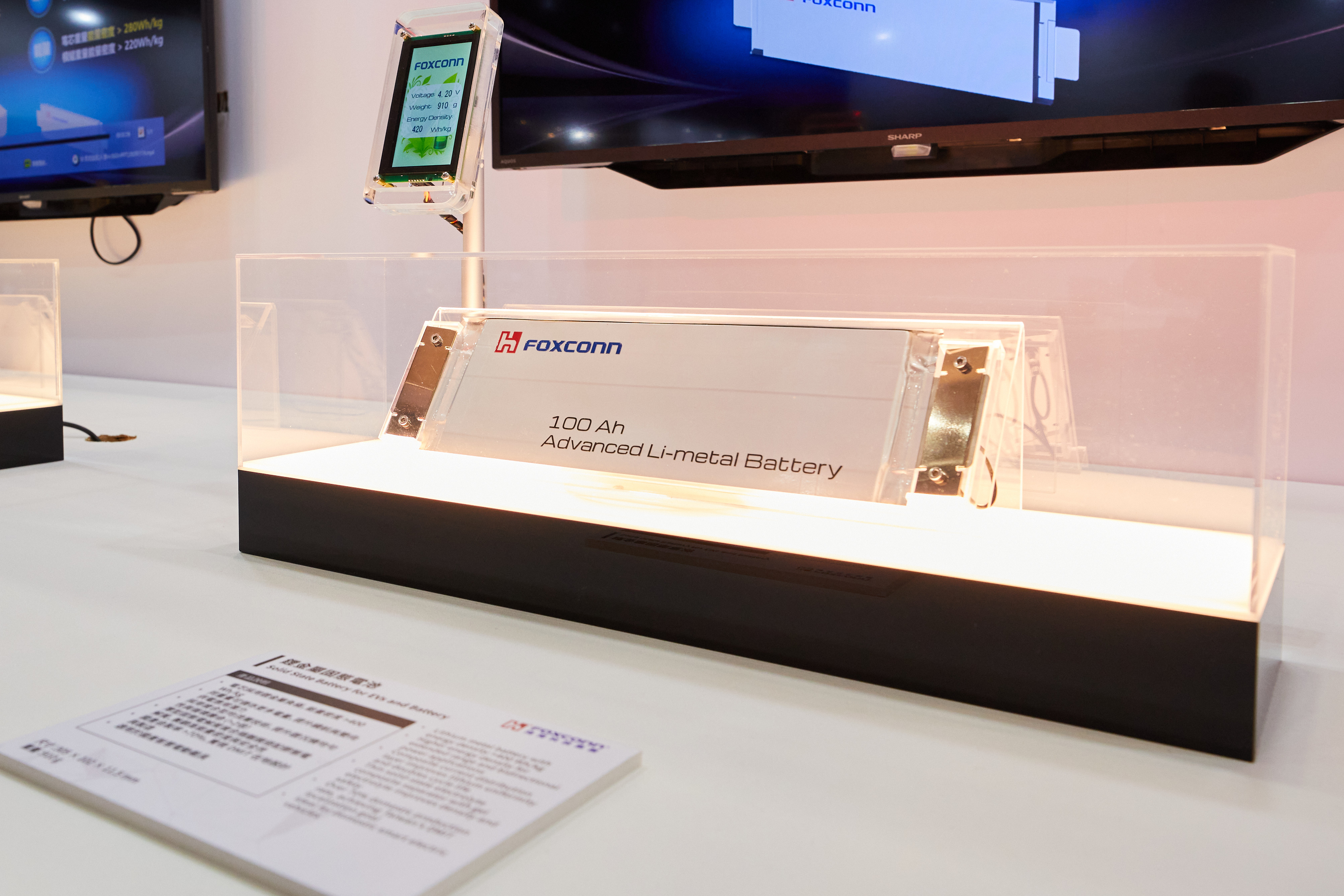

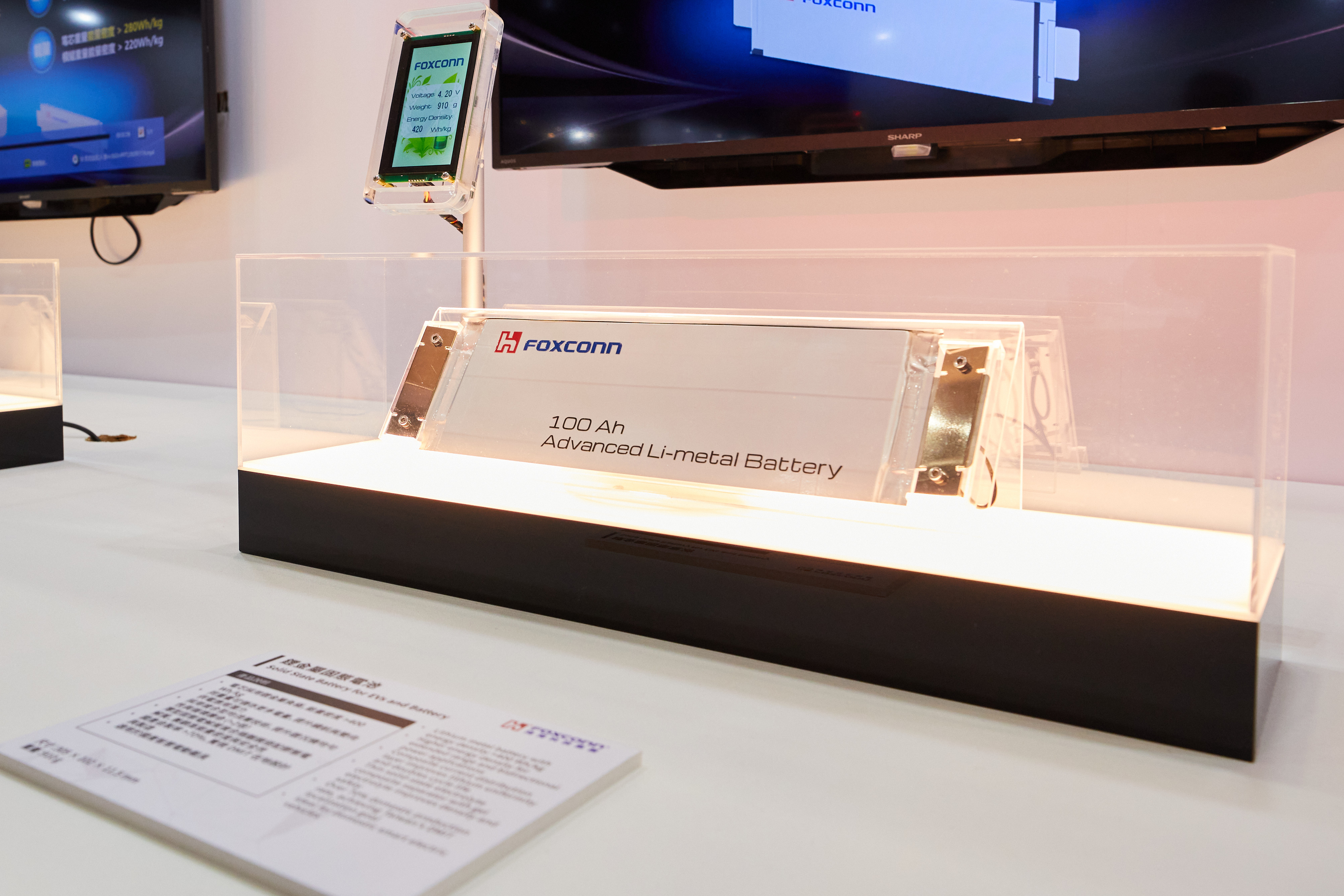

富士康高雄和发电池中心产品亮相 电池技术吸睛大秀垂直整合能力

2025/11/25

富士康高雄和发电池中心产品亮相 电池技术吸睛大秀垂直整合能力

2025/11/25

富士康智慧制造机器人亮相 通过AI练功让机器手臂更灵巧

2025/11/25

富士康智慧制造机器人亮相 通过AI练功让机器手臂更灵巧

2025/11/25

研发与技术

富士康科技集团是科技服务的领先者,以智慧为核心,积极投入“电动车、数位健康、机器人”三大新兴产业,以及“人工智能、半导体、新世代通讯技术”三项新技术领域,致力于共同创造全方位智慧生活。

智能电动车

智能电动车

鸿海研究院

半导体

人才招募

竭诚欢迎怀抱梦想与热情的人才加入,在富士康这个世界舞台上,创造价值、实现梦想